Are you looking for a solid-liquid filtration and separation system for your laboratory?

Do you need to dewater a small volume of fluid for your micro-production but still require an efficient filtration system that achieves results comparable to industrial filter presses?

Are you tired of using outdated Buchner funnels or Nutsche filters for your tests and seeking an alternative that delivers the best solid/liquid separation results?

Do you want a system that allows you to test your products and obtain useful, scalable data and results for potential transition to industrial production?

Are you seeking a modular system that can be tailored to your needs?

Click on the orange button to download for free the pdf report:

“How to choose the right lab filterpress for your application”!

No registration or personal data is required!

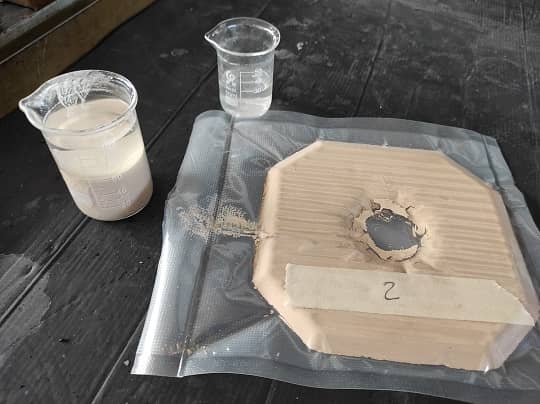

When the characteristics and filtering properties of the fluid to be filtered are not known and it is necessary to carry out preliminary tests before identifying the best type of machine, an excellent solution is to build a small laboratory filterpress which acts as a pilot filtration plant.

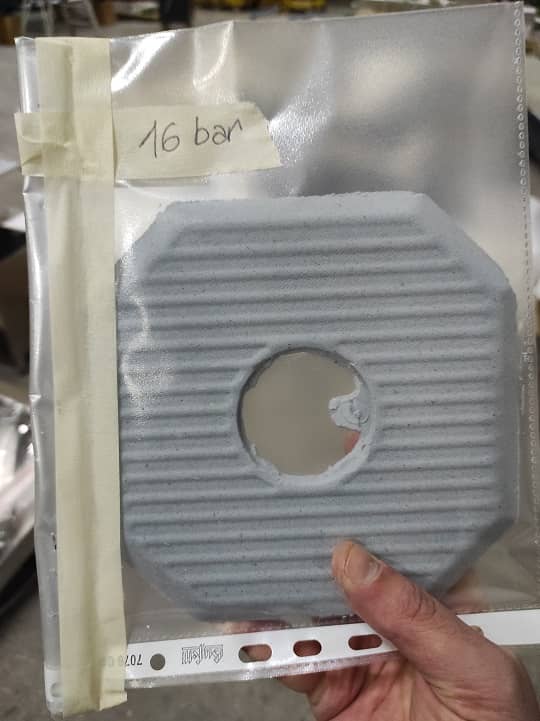

On this equipment it is possible to carry out as many filtration tests as desired, changing all the variables involved.

By using a pilot filter press, all the necessary parameters can be determined easily.

The purpose of using a micro laboratory filterpress is also to investigate new methods of treating the fluid to be filtered, and to do this it is necessary to use a filtration station that can take advantage of all the accessories that can be found on industrial scale machines.

On the basis of the experimental results obtained, the filtration properties of the suspension are evaluated and the representative results are transferred to industrial scale with a regular production filter press.

These devices are ideal not only for laboratories or research and development departments, but also for companies with very small productions.

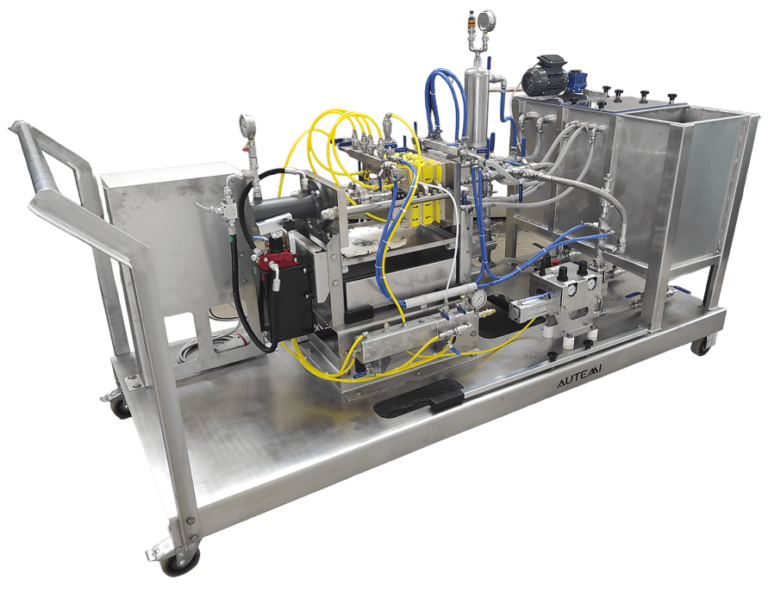

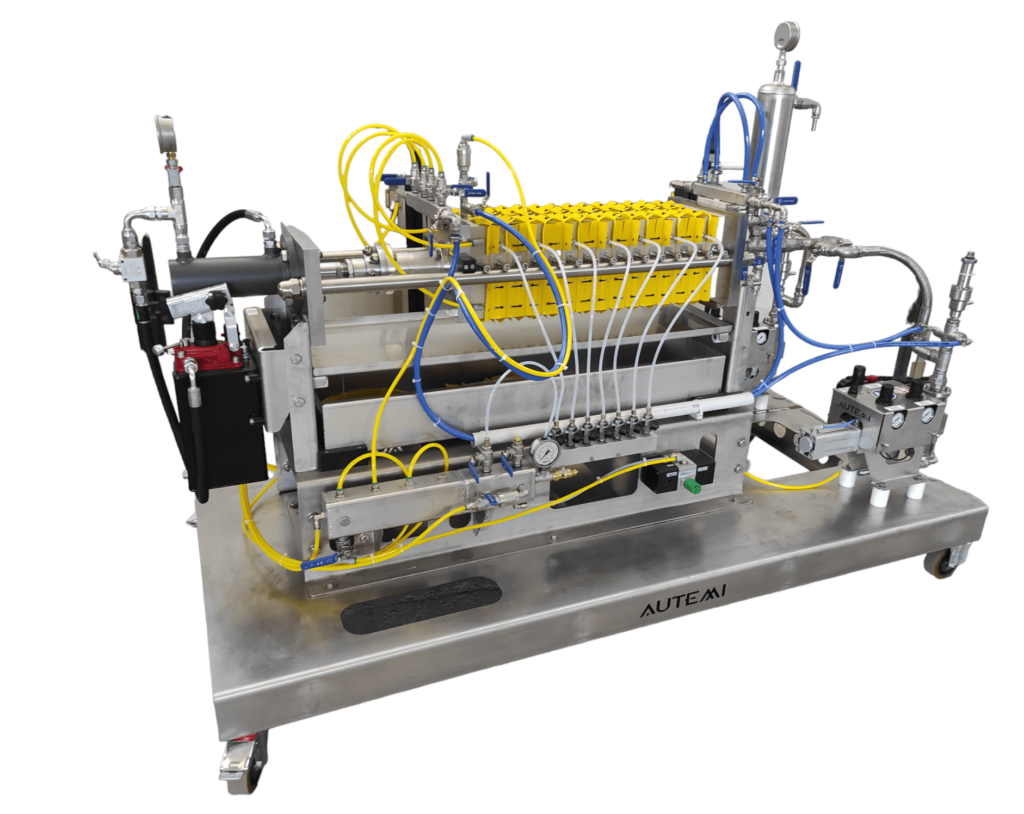

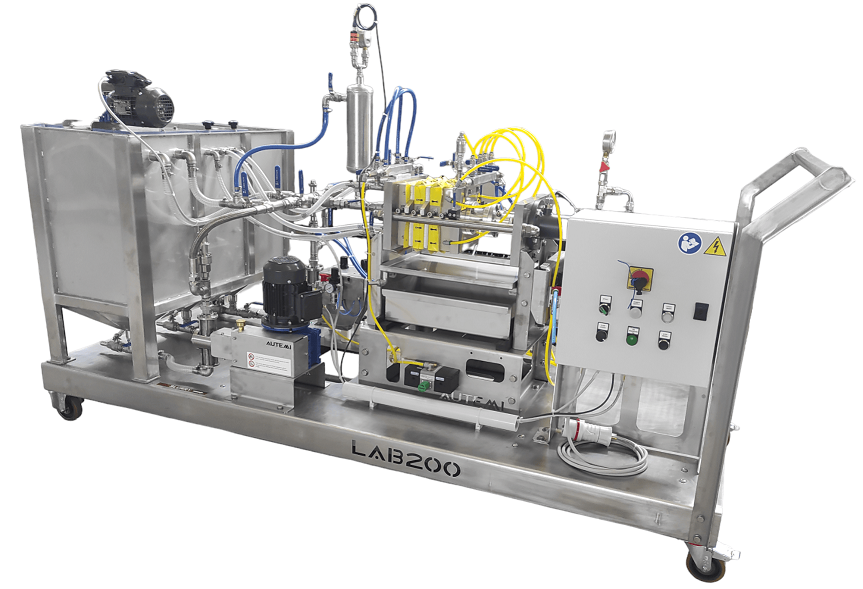

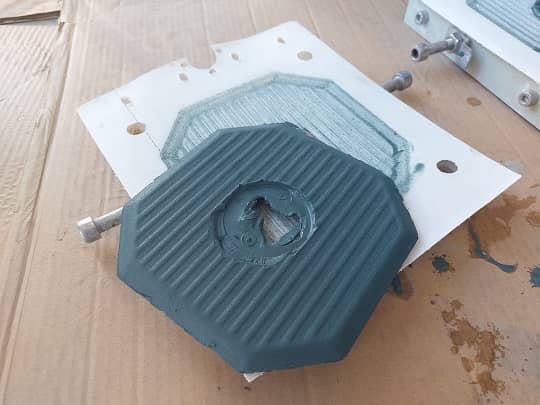

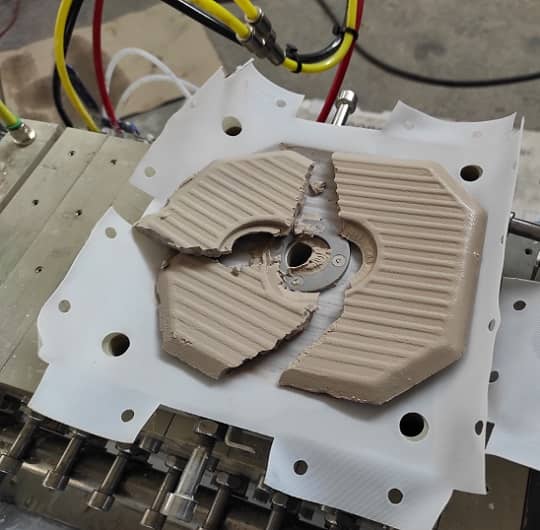

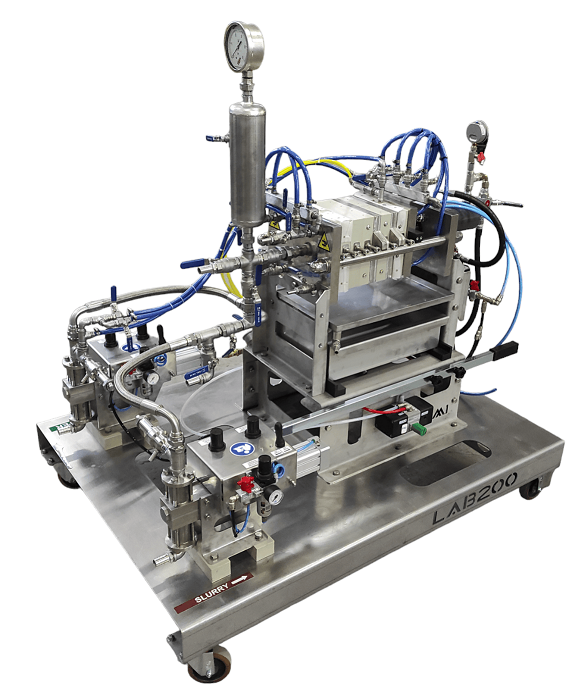

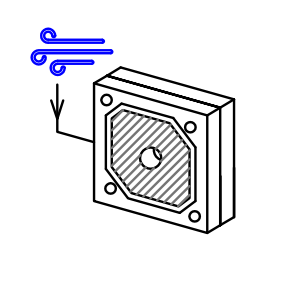

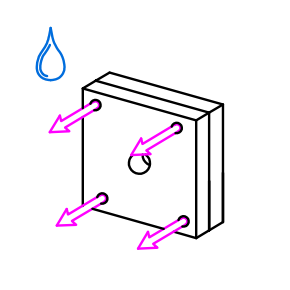

The LAB200 series pilot laboratory filterpress is a miniature industrial machine which is able to perform the same operations as larger machines.

For Example, in this kind of mini-filterpress you can perform:

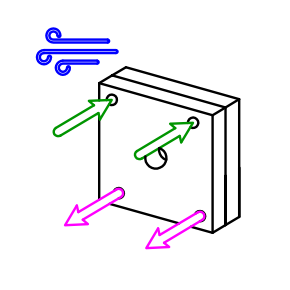

-core blowing and core washing

-cake blowing and cake washing

–membrane squeezing

LAB200 filterpress series is designed for laboratory, R&D department and also mini or micro-production.

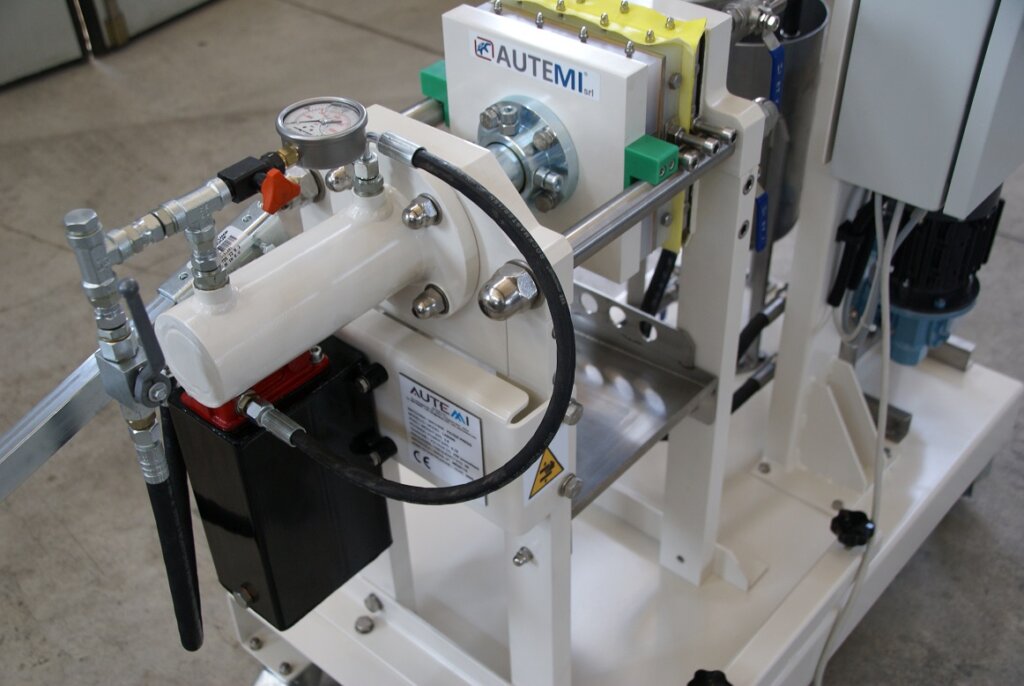

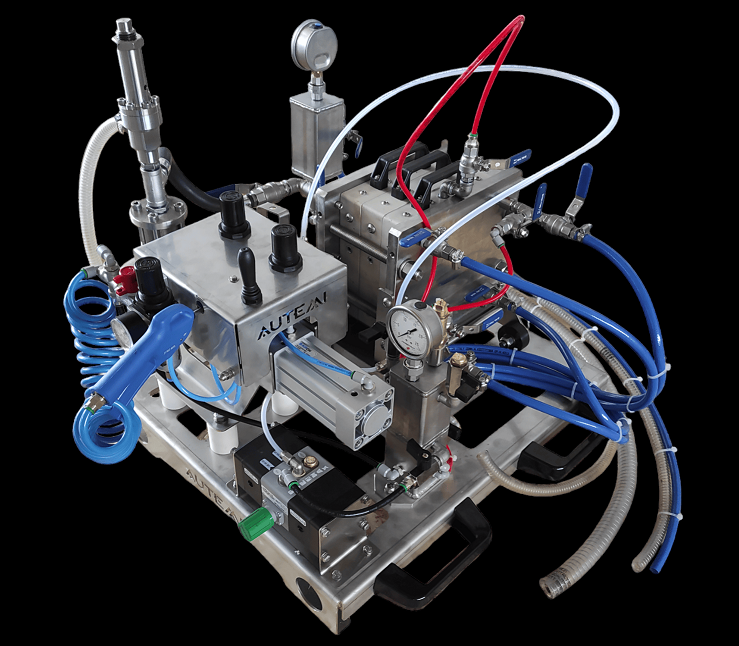

In our range of small filterpresses, also portable or bench versions are available in order to allow customer to perform filtration tests in a very small area or also in different sites away from the laboratory or headquarter.

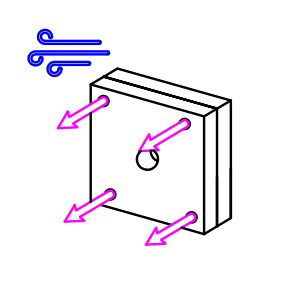

This series can be driven by compressed air only or also by manual human force when at site no power supply or net air is available.

Moreover, the micro-filterpresses models presented here can be supplied in various versions, depending on the customer’s needs, up to the most complete version with all the auxiliaries present to speed up all operations and make the same unit independent.

They can be customised in terms of the number of plates installed (total filtering volume and total filtering surface area), plates material and construction material of the filterpress. In addition, various auxiliary systems can be mounted to create truly independent filtration stations.

Don’t make the classic mistakes that may people make in these cases: in fact, it is often not considered that in order to have a truly complete dewatering station, it is necessary to also have:

PILOT FILTERPRESS supplied by Autemi, represent the ideal solution to dewater small quantity of sludge.

The filterpress station LAB200 is not a simple stand-alone laboratory filterpress, but can be supplied also in a real pilot plant to study a concrete application for a high-fidelity scale-up to an industrial solution.

Moreover, this series of pilot filterpresses can be used to dewater also difficult slurries because these units install all the features we have in a full automatic industrial filterpress.

Click on the orange button to download for free the pdf report:

“How to choose the right lab filterpress for your application”!

No registration or personal data is required!

Efficient sludge and turbid liquid treatment are crucial components in various industrial sectors, ranging from food and chemical processes to water treatment and the study of innovative materials that require a solid-liquid separation during the production process.

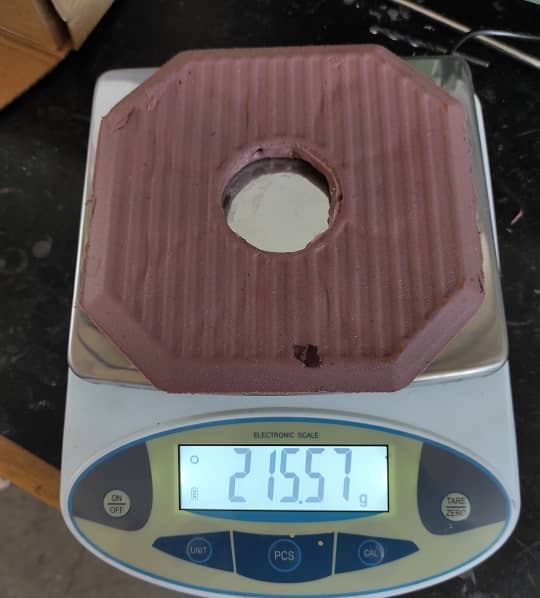

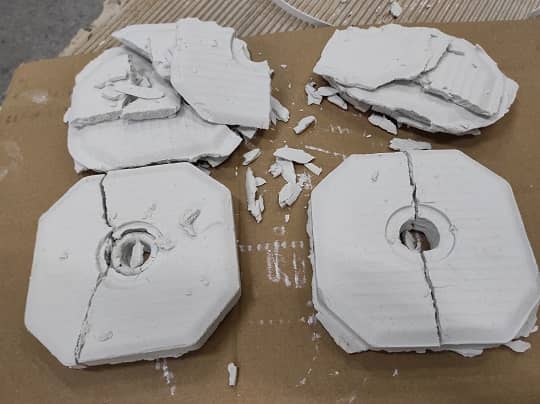

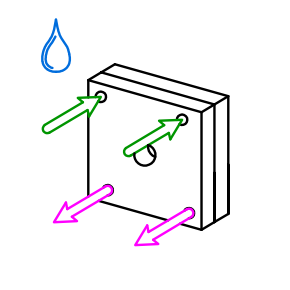

Confronting the challenge of dewatering sludge to obtain the driest possible filter cake necessitates the use of advanced tools.

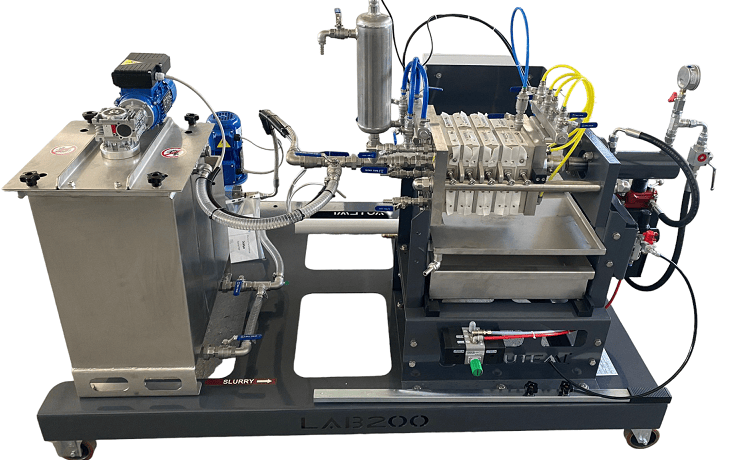

In this context, the “LAB200” pilot filter press emerges as an innovative solution for testing a wide range of sludges and turbid substances, allowing for precise determination of the necessary filtration parameters.

The “LAB200” pilot filter press offers a flexible approach to sludge analysis, successfully handling a wide range of materials.

This versatility is crucial for businesses operating in diversified sectors, facing challenges related to the variable nature of the materials to be treated.

The ability to test different types of sludge provides operators with the flexibility needed to manage complex filtration processes.

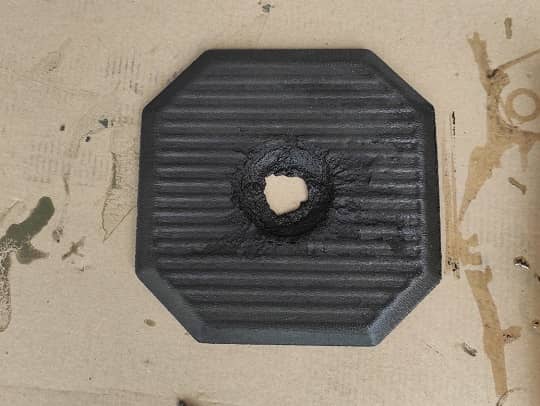

Thanks to its adaptability to various types of sludge, the device can provide detailed data on optimal filtration to minimize the moisture content in the filter cake.

The “LAB200” pilot filter press represents a significant advancement in optimizing sludge dehydration processes. Its flexibility, coupled with the determination of filtration parameters, makes it an indispensable tool for industries aiming to enhance operational efficiency and address continuously evolving environmental challenges.

The implementation of this technology not only provides a competitive advantage to companies but also contributes to global sustainability by reducing waste and improving energy efficiency.

Explore the capabilities of the “LAB200” filter press for effective filtration solutions in your industry, optimizing processes and achieving environmentally friendly results.

Click on the orange button to download for free the pdf report:

“How to choose the right lab filterpress for your application”!

No registration or personal data is required!

LABfilterpress series can be installed with the most important and complete equipment you can find in an industrial filterpress.

All the functionality of an industrial machine are available for your use. In this way you will have the most efficient solid-liquid separation system available in the market.

Whether you have to do microproduction, research and development or build a pilot plant, you will have the opportunity to study all the factors that determine maximum filtration efficiency.

You will have a tool with which you can maximize solid-liquid separation, and you will have all the data you need if you want to scale-up to industrial production.

Otherwise fill the form with all the required information and we will contact you for a tailor made solution for your application

Autemi s.r.l. – Via dell’Artigianato 20 – 48034 Fusignano (RA) – Italy

Ph: +39 0545 62985 – WhatsApp: +39 346 3222007 – Mail: info@autemi.com