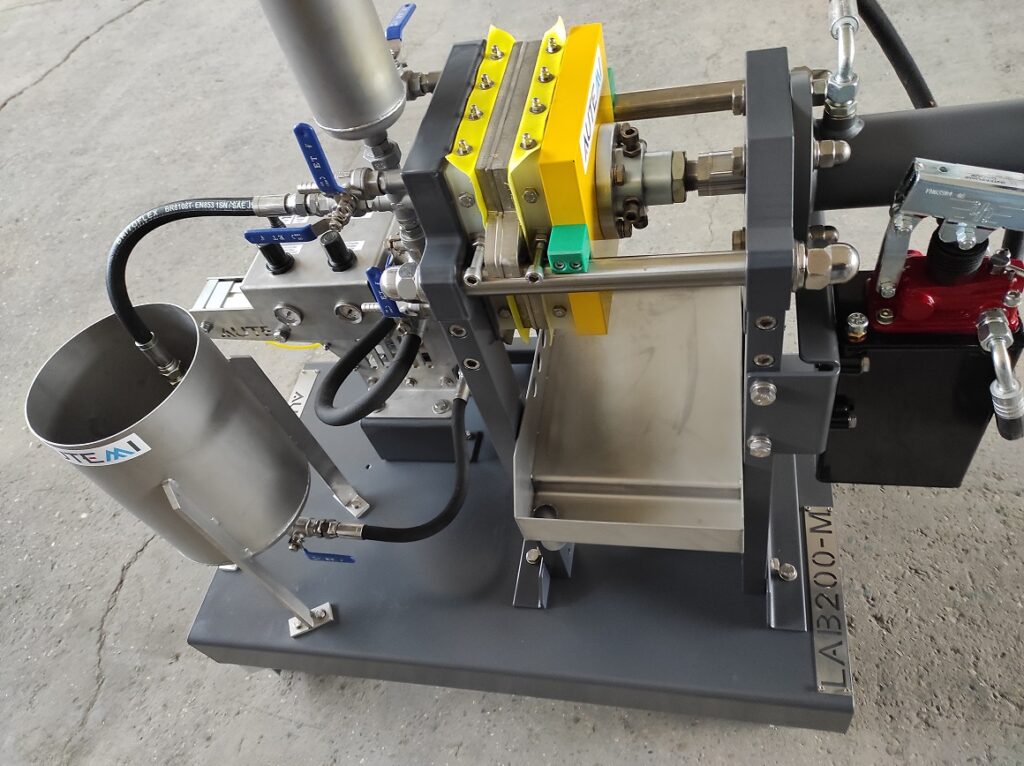

In order to meet the requirements of the majority of customers, both in terms of budget and functionality, we have prepared 6 main versions of our Lab FIlterpress LAB200 series dewatering stations. These versions can be customized in terms of number of installed plates and in terms of construction materials.

The versions here proposed are different in terms of the functions installed and the number and type of auxiliaries provided. From a simple stand-alone Lab Filterpress, it can be upgraded to a filtration station complete with pump, tanks and all the process functions that can be found in industrial filterpresses.

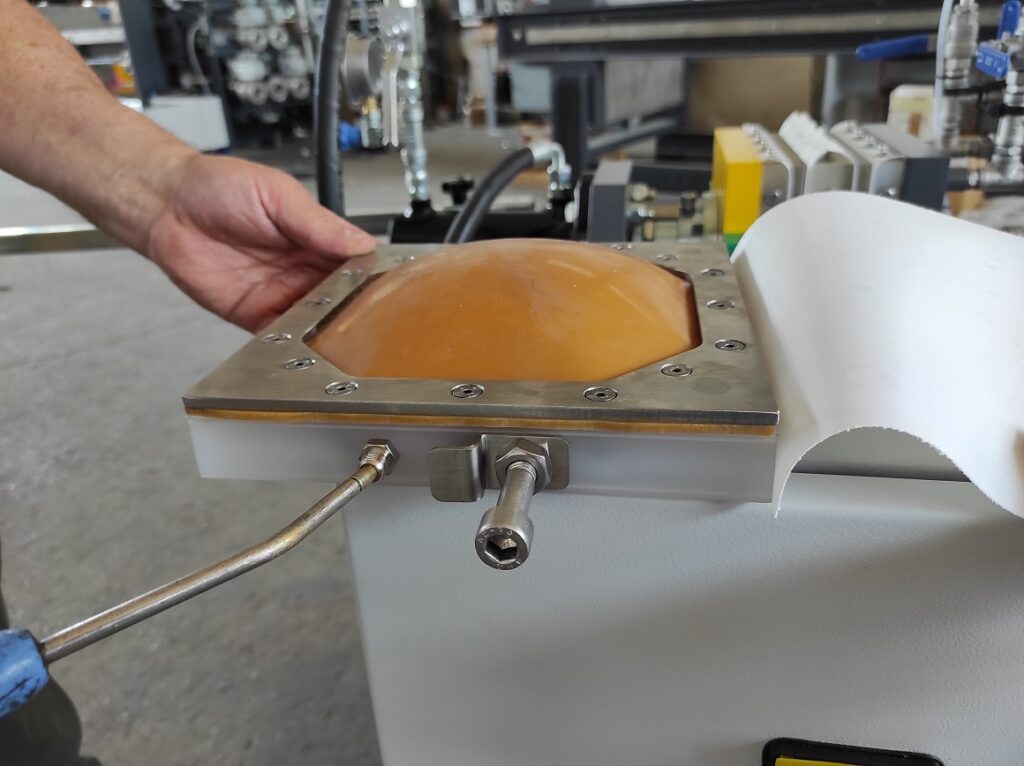

It may happen that you have to filter a sludge/fluid that is difficult to treat (for example, a thixotropic sludge): in this case it may be necessary to use membrane squeezing because with traditional pressure filtration the sludge is still wet and not Palable. In this case, in addition to the diaphragm plate, a suitable pressing system is required to apply pressure up to 15 bar to the diaphragm.

Using compressed air at a lower pressure – for example 6-8 bar – may not be enough to guarantee a good result and may lead to incorrect conclusions. Remember that in the industrial field, squeezing pressure reaches up to 15 bar, therefore it is very important to at least reach the same values.

Moreover, in case it is wanted to study how to shorten filtration time, membrane squeezing can significantly help to reduce the time compared to a traditional filtration: in this case it is possible, for example, to stop filtration at 6-7 bar and then proceed with membrane squeezing up to 15 bar.

It may also be necessary (both in combination with membrane squeezing and without) to carry out a drying phase of the cake (cake blowing) to help its detachment from the cloths and to increase the residual dry content by a few percentage points.

In this case it is highly recommended to use a Lab filterpress that allows an additional inlet and a series of process valves to easily enable this function. It is not enough for the filter press to allow this, but it must be simple and fast to do so, so as to have a complete and efficient apparatus.

This again requires adequate process piping and a stable and efficient pressure generation system.

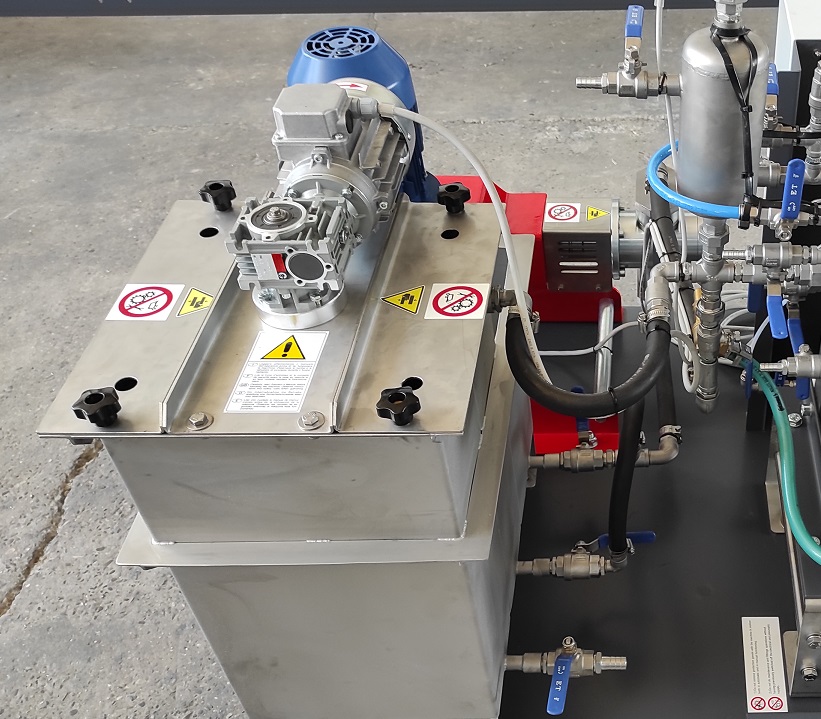

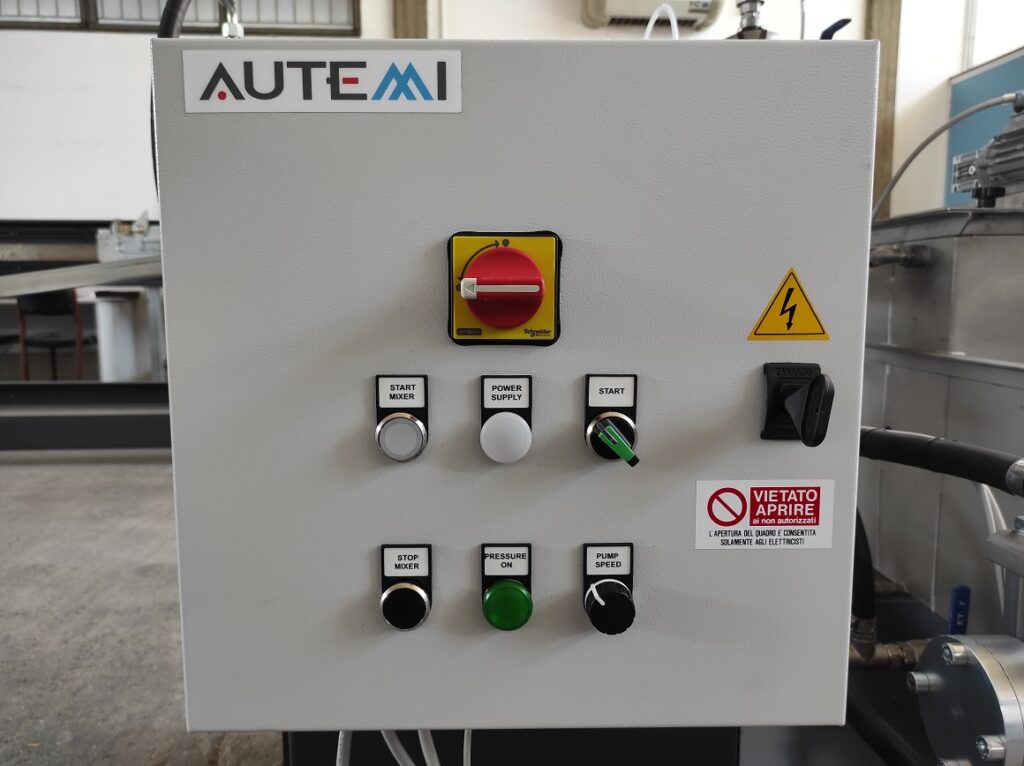

It is necessary to have an appropriate tank with a suitable mixing system: do not forget that many sludges or liquids to be treated tend to sediment quickly. In these conditions it is absolutely necessary to keep the fluid itself in agitation before sending it through the pump to the filter press.

Otherwise, you could obtain a non-representative sample sent to the filterpress that could distort the test and reduce its performance: it often happens that, if the sludge sediments inside the tank without an agitator, only a part of liquid sludge with little solid is sucked. In this case, a much less dry cake would be obtained with a longer filtration time.

Keeping the fluid in agitation increases the filtration efficiency.

It is also important to have a system that allows you to test different thicknesses of filter chambers: there are slurries or fluids that need a thin filter chamber and others for which a larger filter chamber is sufficient.

For this purpose, it is necessary to use a filtration system that allows the filter chamber to be varied.

All LAB200 series of La filterpress allow you to change the thickness of the filter chamber to conduct tests and find the best possible condition.

Never underestimate the importance of having a system that can be effectively cleaned and flushed, especially in terms of process piping.

If slurries or fluids that have a tendency to settle quickly are being filtered, the pilot filterpress must allow the various sections of piping to be intercepted to perform a dedicated flushing in order to quickly and efficiently restore normal operation.

In order to do this, it is necessary to use an additional tank for the flushing water and to have a piping together with a system of valves that allows to use the same pump of the filter press also for the flushing and washing with water. Don’t undervalue the aspect of proper cleaning of the filter press in order to always get the best results.

Having a system that does not allow rapid and effective flushing of the pipes can be a serious problem when working with fluids that are difficult to treat, in addition to the considerable amount of time that, without this system installed, is necessary to keep the filtration station in proper condition.

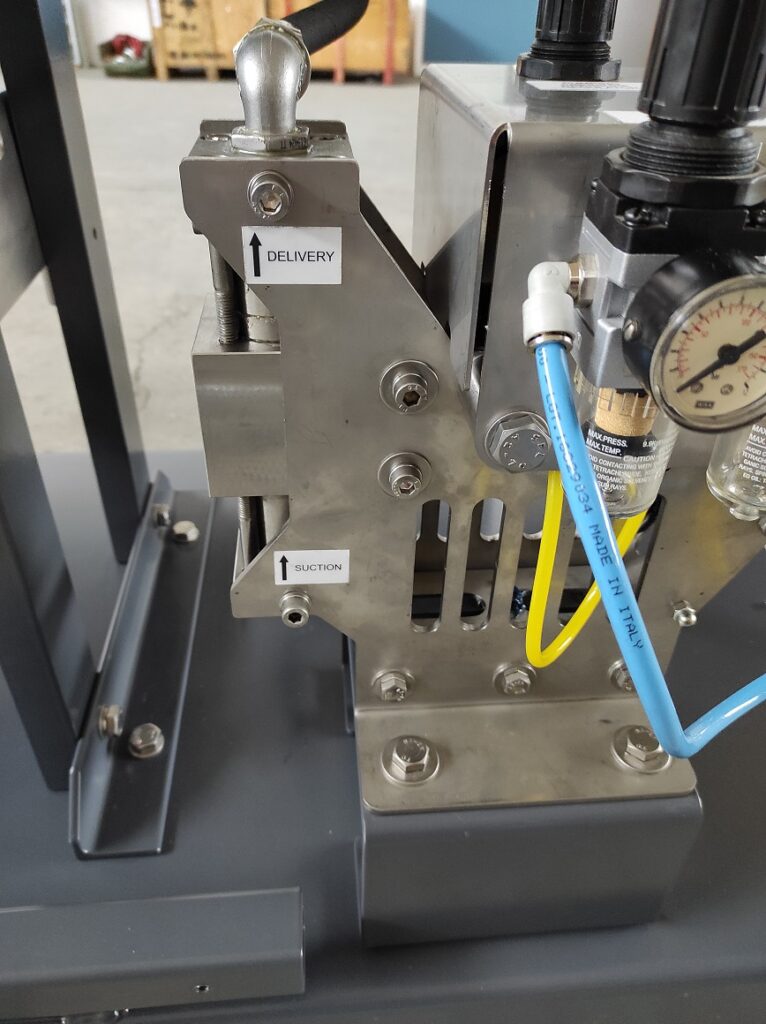

Remember also, that it is necessary to use a high pressure feeding pump to feed the Lab Filterpress, so that the full potential of the filtering system is exploited.

In industrial applications, filtration pressures reach at least 16 bar, so, especially if you have to study the behavior of different fluids/sludges between them, do not stop at lower pressures but use a system that reaches the highest pressure values achievable.

Check out our 6 versions of Lab Filtetrpress, from the basic one to the advanced complete dewatering station to satisfy your specific needs.

If you are looking for bigger filterpress for your application, we have a complete range of industrial machineas for your request.

Autemi s.r.l. is an Italian company who produces plate filterpresses and feeding pumps for a lot of industrial applications. The same features you can find in the small lab-scale filterpresses, you can find in industrial size when you need to dewater bigger volumes of liquid or slurries. Depending on the degree of automatism, we have several options and model that for sure will fit your needs.

Please take a look at our range and don’t hesitate to contact us in case you need more informations!

Fill the form with all the required information and we will contact you for a tailor made solution for your application

Autemi s.r.l. – Via dell’Artigianato 20 – 48034 Fusignano (RA) – Italy

Ph: +39 0545 62985 – WhatsApp: +39 346 3222007 – Mail: info@autemi.com