Considering that we have different versions and models of laboratory filterpresses, you may ask yourself what is the differences, in a few words, between al the products in our portfolio.

First of all, as you certainly already know, every filterpress needs a feeding pump in order to feed the filterpress with the liquid to be filtered inside the filtering plates of the press itself.

This pump is not a common pump, but is an high pressure pump which needs to reach a pressure of about 12/15 bar, because the filtration with a filterpress can reach easily 12/15 bars of working pressure.

Most of the time, if you stop the filtering pressure at lower value (unless you have a membrane squeezing system as in some of our models), for example 6-7 bars, you will obtain a partially dewatere exhaust cake.

This means that you don’t obtain the lowest humidity possible in exhaust cake (also called residual panel).

In our portfolio, we have basically this choices:

Basically, there’s no such difference;

Some customers prefer a unit that doesn’t require any power supply but require only compressed air – that’s why we have the pneumatic series.

Some other customers prefer unit with power supply and electric pump, and that’s why we offer also electric version.

In general electric version is more like industrial filterpresses, because in real application in 90% of the application an electric pump is installed and the management of the start/stop of the pump is pretty much the same between our electric series of LAB filterpress and industrial filterpress.

Both pneumatic or electric pump can reach the same pressure of 15 bar; of course the pneumatic version is cheaper.

The results in terms of dewatering doesn’t change between Electric or Pneumatic; is only a choice of the customer.

In the end, sometimes the customer want to provide itself the pump and the other equipments, so that’s why we can supply the stand-alone version LAB200-SA or LAB200-TRAVEL.

In this cases we can also supply the feeding pumps (pneumatic or electric) as stand-alone item and the customer will have to provide to connect the pump with the filterpress feeding.

In a lab-scale filterpress, like in the real applications, there are always other equipments like:

– slurry tank: the tank from which the pump suction the slurry and feed the filterpress

– filtrate tank: the tank in which the filtered liquid is collected

– water pump: the pump which is useful to wash and flush al the piping of the filterpress, in order to clean the equipment in the piping

– compressed air system: this is a system to deliver the compressed air inside the filterpress and in the piping in order to perform special tasks that can improve the efficiency of filtration.

Customer can decide to provide itself this auxiliary equipment, or in some case to use basic filterpress without special tasks.

In this cases we can also supply the feeding pumps (pneumatic or electric) as stand-alone item and the customer will have to provide to connect the pump with the filterpress feeding.

Here is a short explanations of the differences between the models.

For the detailed features, please visit the dedicated web-page for each model

LAB200-CEFS and LAB200-EFS are the elctric series.

Electric means that the unit has an electrical panel which manage the feeding pump.

The difference between CEFS and EFS depends on the tanks: CEFS version has got from 2 to 3 tanks, one of them has got the electrical mixer for slurry tank, which is very important for slurries that settle very quickly.

Instead, the EFS has got no tanks at all (in charge to the customer).

LAB200-CPFS and LAB200-PFS are the pneumatic versions.

Pneumatic means that the unit don’t require any power supply, because compressed air (6 bar) is enough for pilot station functioning, as the feeding pump is pneumatic.

Also in this case, the difference between CPFS and PFS depends on the tanks: CPFS version has got from 2 to 3 tanks (no mixer in this case), instead, the PFS has got no tanks at all.

Then, inside each one of this models (CEFS, EFS, CPFS and PFS),

you can find n°4 different versions, depending on the feature installed and process you can run:

BASIC:

is the simplest version, with only feeding pump

STD:

in this version you can perform cake blow and cake wash (washing pump is not supplied), and also core-blow and channel blow, because a pneumatic low pressure generation system is installed on board.

Cake Blow is useful to reach some more points of dryness in residual cake and in general allows a better detachment of the cake from the clothes (in a lot of applications, but not in everyone).

PLUS:

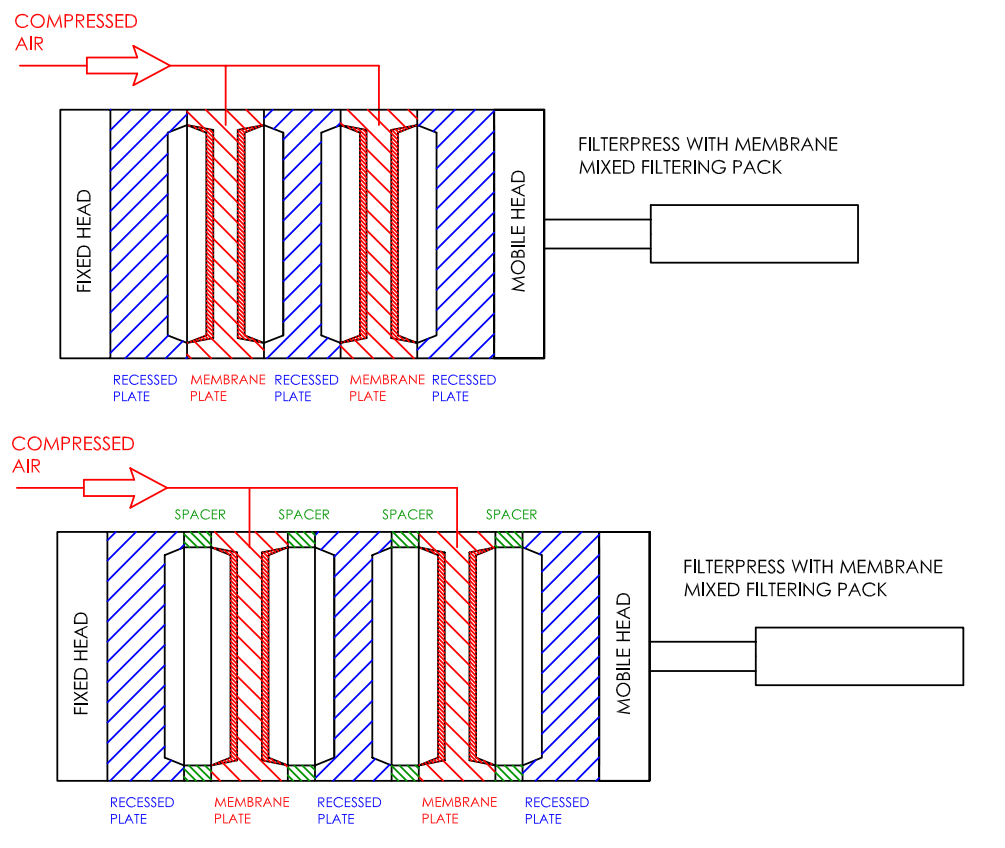

in this version you can find all the installed features that is available on STD version, but in addition you can also install membrane plates typology with high pressure squeezing system, that allows you to obtain a dryer cake in order to reduce the residual humidity as much as you can. With this kind of version you can install both standard recessed plates or also membrane plates.

In order to perform membrane squeezing an high pressure generation system is installed on board to allow customer to reach 15 bar of pressure (from 6 bar of net pressure required).

Membrane squeezing filtrations, allow to obtain some benefits showe in the next chapter.

TOP:

in this version you can find all the installed features that is available on PLUS version, but in addition, a washing pump is installed. With the washing pump you can perform cake washing, if you need to wash the cake for your application, and also you can use this pump to flush the piping of the pilot filterpress, if you need to wash the station properly before performing a new filtration cycle with a different slurry or liquid and you want to reduce the contamination between the previous test and the new one.

In the end, the stand alone versions available are LAB200-SA version or LAB200-TRAVEL.

In both versions, only the filter press is supplied without any other accessories or auxiliaries (pumps, tanks, air generation systems, etc.).

All the other equipment like pump, tanks, ecc, must be provided by customer.

The main differences between the two versions are these:

As we have seen in the previous chapters, in all the PLUS and TOP versions of all the LAB200-EFS, LAB200-CEFS, LAB200-PFS and LAB200-CPFS models, is possible to perform the membrane squeezing filtration in addition to the standard filtration with recessed filtering plates.

Membrane squeezing filtrations, allow to obtain some benefits and it is used in this cases:

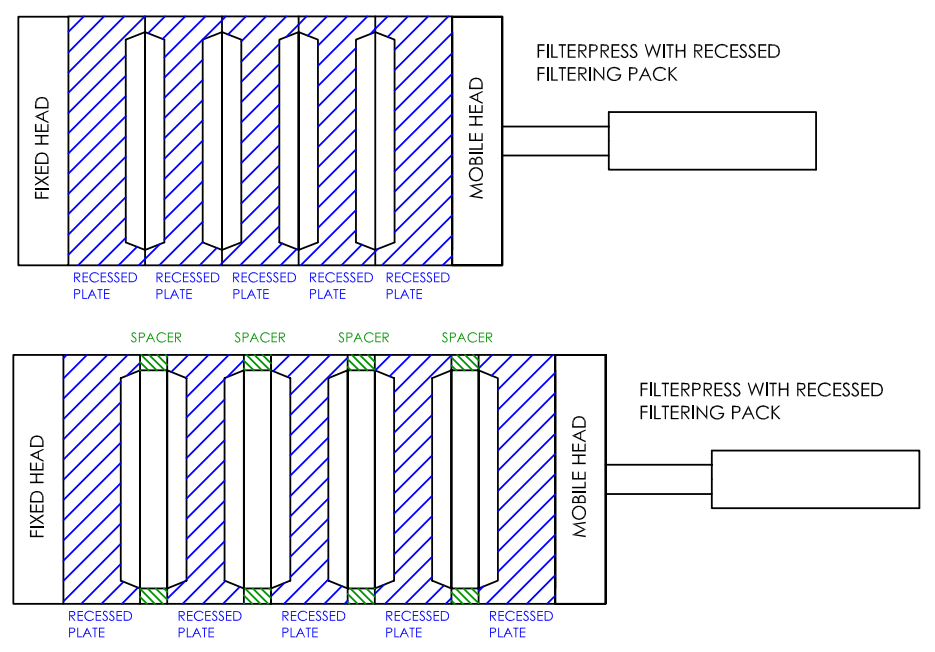

In the same PLUS or TOP versions of all the LAB200-EFS, LAB200-CEFS, LAB200-PFS and LAB200-CPFS models, is possible to install:

A maximum of N° 8 recessed plates and N°7 membrane plates (with or without spacers) – MEMBRANE FILTRATION WITH MIXED PACK (is called mixed pack because the membrane is between a recessed plate and the other one).

Check out our 6 versions of Lab Filtetrpress, from the basic one to the advanced complete dewatering station to satisfy your specific needs.

Fill the form with all the required information and we will contact you for a tailor made solution for your application

Autemi s.r.l. – Via dell’Artigianato 20 – 48034 Fusignano (RA) – Italy

Ph: +39 0545 62985 – WhatsApp: +39 346 3222007 – Mail: info@autemi.com